| Availability: | |

|---|---|

| Quantity: | |

XC-L85 Paper Cup Machine (40ml-330ml)

Description

medium speed paper cup forming machine is based on the vertical axis paper machine. Through innovation and improvement, the stability and production speed of the wheel machine have been greatly improved. It is suitable for the production of single and double-sided coated hot and cold beverage paper cups through continuous processes such as feeding, middle sealing into cylinder, cup mouth lubrication, upper curling, cup bottom, bottom heating, rolling, and finished product blowing. cream paper cups, medium speed paper forming machine is an upgraded version of the vertical axis paper cup machine; The overall steel plate body and the oil-leading system long-term normal and stable operation of the

Technical Parameter

XC-L85 | |

Cup size | (D1) φ 43-85mm (H) 36-115mm (D2) φ 32-62mm (h) 4-9mm

|

Applicable Paper | 150-250gsm ( single PE) 150-380gsm (single PE/double PE) with ultrasonic(Optional) |

Production speed | 75-85pcs/min |

Electrical requirement | 7.5KW 380V 50Hz |

Compressed air | 0.4m³/min ,Air source request (double PE): 0.4-0.6 Mpa |

Weight | 1600KG |

Wooden case dimension | 2400*1100*1700mm (L*W*H ) |

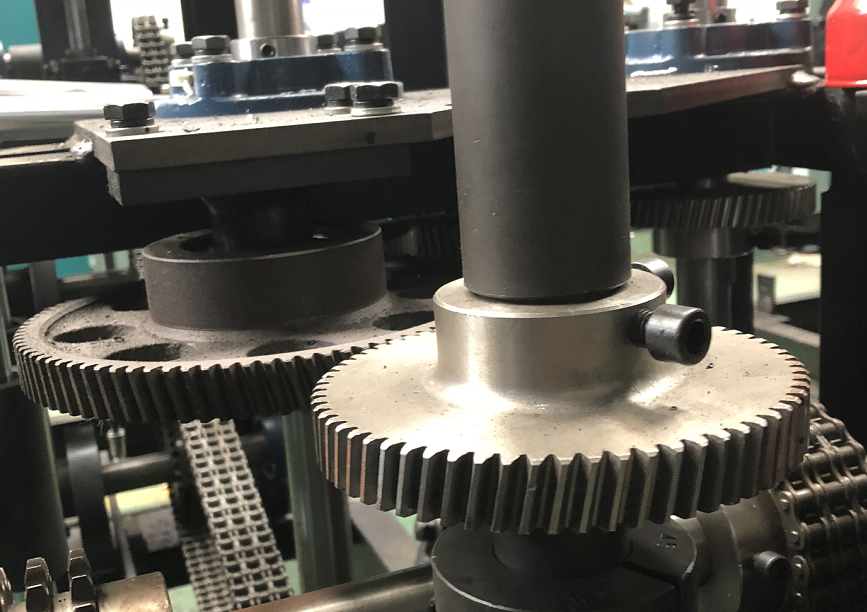

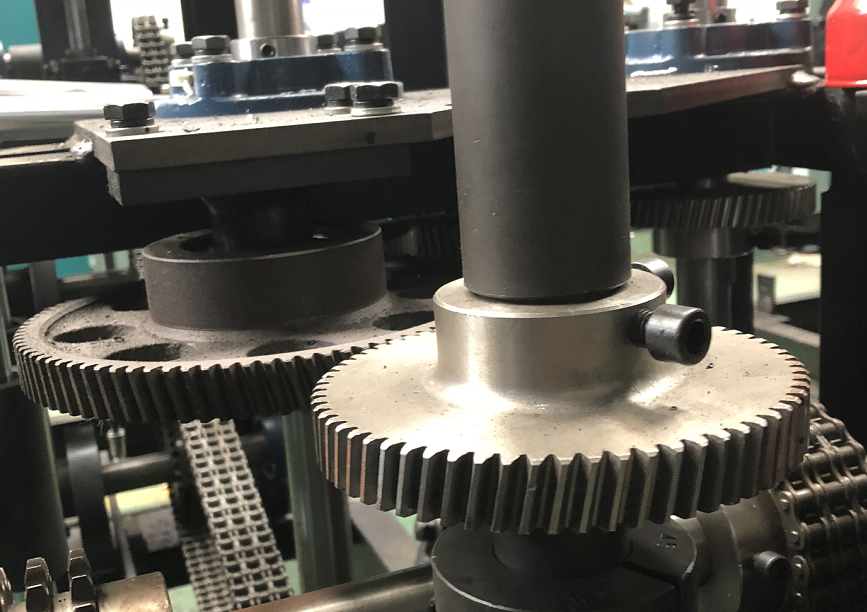

cup bottom forming Bottom paper station

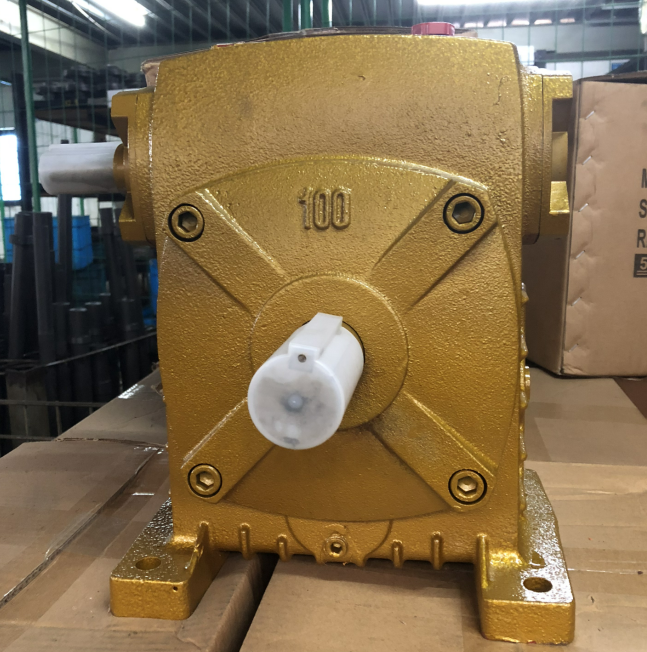

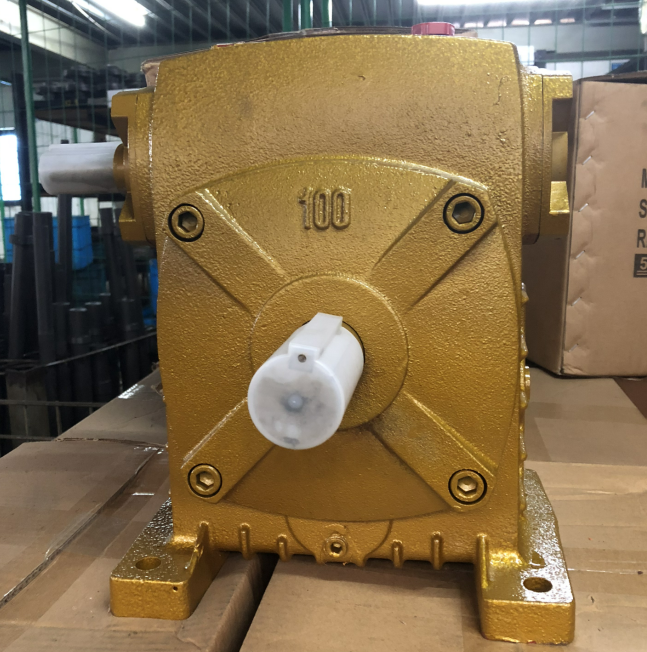

Oil supply and oil distribution system

Advantage and improvement:

1.Gear drive,more stable running,speed up and reduce the cost of maintenance.

2.100 type speed reducer is used instead 80 type.higher transmission efficiency, better parallelism, sensitivity, and precision for use.

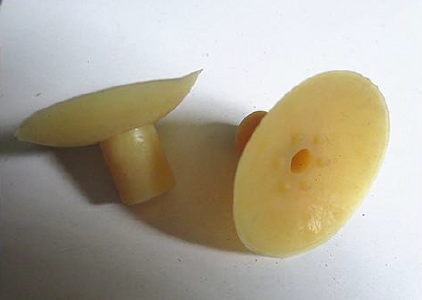

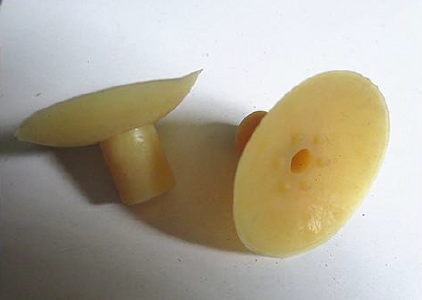

3.Double layer sucker is used for cup fan sucked to guarantee powerful sucking and more successful.

The using life is much more longer than normal sucker.

4.Two step paper feeding 5.Automatic oil lubrication

XC-L85 Paper Cup Machine (40ml-330ml)

Description

medium speed paper cup forming machine is based on the vertical axis paper machine. Through innovation and improvement, the stability and production speed of the wheel machine have been greatly improved. It is suitable for the production of single and double-sided coated hot and cold beverage paper cups through continuous processes such as feeding, middle sealing into cylinder, cup mouth lubrication, upper curling, cup bottom, bottom heating, rolling, and finished product blowing. cream paper cups, medium speed paper forming machine is an upgraded version of the vertical axis paper cup machine; The overall steel plate body and the oil-leading system long-term normal and stable operation of the

Technical Parameter

XC-L85 | |

Cup size | (D1) φ 43-85mm (H) 36-115mm (D2) φ 32-62mm (h) 4-9mm

|

Applicable Paper | 150-250gsm ( single PE) 150-380gsm (single PE/double PE) with ultrasonic(Optional) |

Production speed | 75-85pcs/min |

Electrical requirement | 7.5KW 380V 50Hz |

Compressed air | 0.4m³/min ,Air source request (double PE): 0.4-0.6 Mpa |

Weight | 1600KG |

Wooden case dimension | 2400*1100*1700mm (L*W*H ) |

cup bottom forming Bottom paper station

Oil supply and oil distribution system

Advantage and improvement:

1.Gear drive,more stable running,speed up and reduce the cost of maintenance.

2.100 type speed reducer is used instead 80 type.higher transmission efficiency, better parallelism, sensitivity, and precision for use.

3.Double layer sucker is used for cup fan sucked to guarantee powerful sucking and more successful.

The using life is much more longer than normal sucker.

4.Two step paper feeding 5.Automatic oil lubrication